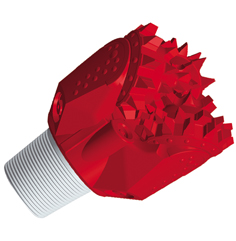

Tricone Bit

Опис на производот

Overview of tricone rotary drill bits for Sale

Tricone bit is mainly used in drilling, exploration, petroleum and trenchless as pilot bit.

According to cutting material, Tricone bit can be divided into tricone bit for well drilling and Steel tooth Bit.

TCI bit adopts high-strength and high-toughness hard alloy teeth, optimized design of tooth row number, tooth number, tooth exposure height, and unique alloy tooth shape, giving full play to TCI bit's high wear resistance and excellent cutting ability.

New wear-resistant material is applied to weld the tooth surface of the Steel tooth bit, which can maintain the high penetration rate of the Steel tooth bit and improve the life of the cutting tooth of the bit.

According to the type of bearing, the tricone rock bit can be further divided into metal seal bearing and rubber seal bearing.

Tricone Drill Rock Bit for Sale Features

High strength and toughness carbide teeth are adopted to improve the impact resistance of teeth and reduce the rate of broken teeth;

Optimized design of tooth row number, tooth number, exposed tooth height, and unique alloy tooth shape, giving full play to the cutting ability and cutting speed of the tricone rock bit;

The clamping roller is adapted to withstand high drilling pressure;

Insert and weld the grinding gold in the inner hole of the roller to improve the anti-bite ability of the bearing;

The use of high saturated nitrile rubber O seal ring, the optimization of sealing compression to improve the reliability of bearing seal;

Adopt an all-rubber oil storage capsule that can limit the pressure difference and prevent drilling fluid from entering the lubrication system, provide good lubrication for the bearing system, ensure the normal operation of "O" seal ring, and improve the working life of the drill bit;

Adopt a new grease with a high-temperature resistance of 250℃ and low wear to improve the high-temperature resistance of the bit sealing lubrication system.