FTP FUME TREATMENT PLANT

ఉత్పత్తి వివరణ

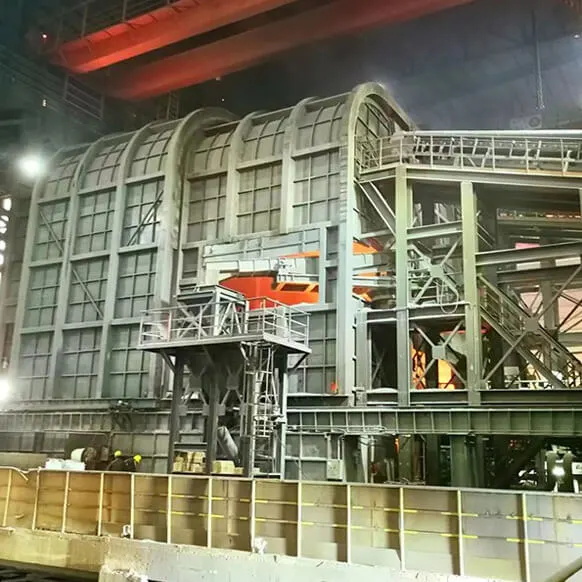

FTP FUME TREATMENT PLANT

In the fume treatment plant aluminium smelter, the electric furnace flue gas is collected through a gas collection hood and enters the main pipeline. Sparks in the exhaust gas are extinguished through a flame arrester, and then the exhaust gas enters the bag dust removal system. From the inlet of the bag dust collector, dust gas enters the filter area of the warehouse, and the remaining dust enters the filter area evenly with the airflow. The filtered clean gas enters the box through the filter bag. Lift valve. The exhaust pipe is discharged and then discharged to the dust standard through an induced draft fan.

Basic principle - "Dust removal equipment serves the production of the furnace body". Dust removal equipment should not affect the normal production process and operation of the fume treatment plant aluminium smelter, and should not hinder the maintenance and repair of the furnace equipment.

The primary principle is "reliable operation". The system operates reliably and stably for a long time, eliminating common problems such as burning cloth bags, dust accumulation in air ducts, and air volume attenuation.

Adopting advanced technology - designing for the specific conditions of the fume treatment plant aluminium smelter in this project, adopting advanced and mature technology, and not simply applying the model of other similar furnaces.

Excellent performance to price ratio - optimized design, saving investment in one go, low energy consumption during long-term operation, and good environmental protection effect.

FEATURES

FUME TREATMENT PLANT ALUMINIUM SMELTER FEATURES

CHNZBTECH fume treatment plant aluminium smelter with small investment, high flexibility, limited dust emission features. Diverse application for traditional top charging EAF, continuous horizontal charging EAF, to ladle furnace, Vacuum Degasser, Submerged arc furnace dust collection.

TYPES

RANGES OF PRODUCTS AMONG FUME TREATMENT PLANT ALUMINIUM SMELTER

A complete electric furnace dust removal system in a foundry and steel mill includes four parts: dust hood, ventilation duct, dust collector, and fan.

Ventilation duct is a channel for transporting dusty airflow, which connects parts such as the vacuum hood, dust collector shoulder machine, etc. into one. Whether the pipeline design is reasonable or not will affect the effectiveness of the entire dust removal system. Therefore, it is necessary to comprehensively consider various issues in the design of Luodao in order to obtain a more reasonable and effective solution.

WORKING

WORKING PRINCIPLE OF EAF DUST REMOVAL SYSTEM

Pre treatment: Use a wet or dry dust collector to remove smoke and harmful gases.

Filtration: Filter particulate matter, harmful gases, and suspended solids to purify air.

Purification: Remove harmful gases, toxins, odors, etc.

COMPOSITION

COMPOSITION OF ELECTRIC FURNACE DUST REMOVAL SYSTEM

The electric furnace bag dust collector consists of a shell, a filter bag, an ash hopper, an ash discharge device, a bracket, and a pulse cleaning system.

The electric arc furnace dust collector is composed of a box assembly, a filter bag assembly, a guide device, a pulse blowing system, an ash discharge system, a control system, an offline protection system, etc.