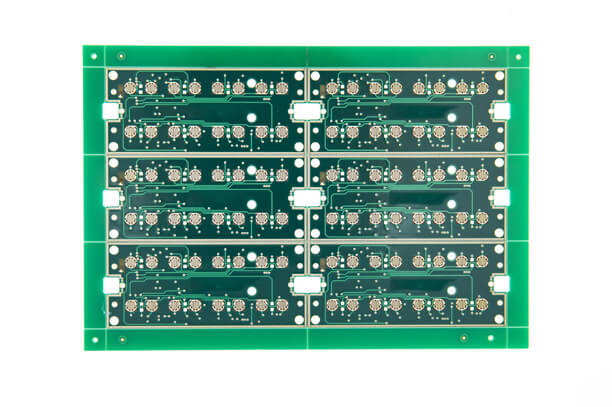

Fastlink Electronics Rigid PCB

תיאור מוצר

We can provide you with up to 64 layers, 12oz copper, HDI, high frequency, high TG, flex, MC pcb from prototype to mass production.

As a rigid pcb manufacturer, Fastlink Electronics offers the highest quality printed circuit boards at the most competitive pricing. Whether you need a few quick-turn PCB prototypes or mass production, our world-class manufacturing can meet your specialized PCB needs with rigid pcb fabrication assembly.

Combining years of experience with the latest in high-tech manufacturing efficiencies allow our pricing to be among the most competitive. Our boards are manufactured based on IPC guidelines and comply with ISO 9001:2015, UL, and RoHS standards.

Introduction to Rigid Polyimide PCBs

Rigid PCBs, or Printed Circuit Boards, are a type of circuit board that is commonly used in electronic devices. A rigid pcb assembly is made up of a flat sheet of insulating material, such as fiberglass or epoxy resin, with conductive pathways etched onto its surface. These pathways, also known as traces, connect different electronic components and allow for the flow of electrical signals throughout the board.

Rigid PCBs are popular due to their durability, reliability, and the ability to create complex circuits in a small area. They are used in a wide range of industries, including consumer electronics, medical devices, aerospace and defense, and industrial automation.

There are several types of rigid PCBs, including single-layer, double-layer, and multi-layer PCBs. Single-layer PCBs have only one layer of conductive pathways, while double-layer PCBs have two layers. Multi-layer PCBs can have four or more layers, and are used for complex circuits that require more routing options.

key Considerations when Designing a Rigid PCB

Rigid pcb board design is an important aspect of the PCB manufacturing process. The design of a PCB determines the overall performance and functionality of the electronic device. Here are some key considerations when designing a rigid PCB:

PCB Layout Guidelines:

The layout of the PCB is critical for ensuring proper functionality and reliability. Proper layout includes the placement of components, the routing of traces, and the spacing between them. The layout should also take into account the heat dissipation and electromagnetic interference (EMI) considerations.

Components and their Placement:

The placement of electronic components on the PCB is essential for proper functionality and reliability. The components should be placed in such a way that they are easily accessible for installation, maintenance, and repair. The placement should also allow for proper heat dissipation and EMI considerations.