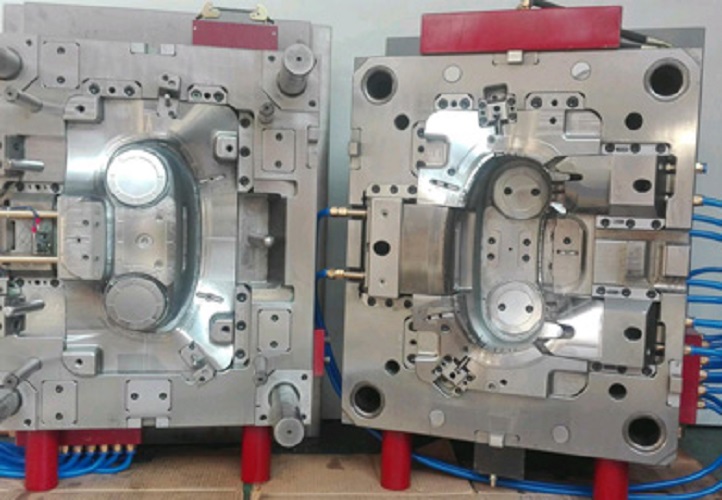

Die Casting Mould

產品說明

Die Casting Mould

Die casting mould is a method of casting liquid die forging. It is a process completed in a special die casting moulding machine.

The major advantage of mould die casting is that thousands of castings can be produced quickly by die casting mould supplier, die casting mould factory, die casting mould manufacturer through one mould. All mould components and parts of die castings are manufactured in mass mount at relatively low unit costs.

Features of Die Casting Mould

Die casting mound technology offers many outstanding features which include:

High corrosion resistance

High strength and hardness

High thermal conductivity

High electrical conductivity

Good processing properties

As the die casting mould supplier, GM-TECH provides you with CNC or ultrasonic removal of the part nozzle, rotary hole, tapping, and so on. Since there are many benefits of the die casting mould, please do not hesitate to contact us if you are interested in our products.

Specification of Die Casting Mould

Part material zinc alloy

Cavity 1

Mould steel H 13

Mould steel 1.1730

Mould life 10W

Mould standard HASCO

Mould structure direct ejection

Exporting country Russia

Leadtime 5 weeks

Mould quality customer satisfaction 99%

FAI pass rate 99%

Project cooperation service customer satisfaction 98%

How does Die Casting Mould Work?

The basic working process of the die casting mould cnc components is as follows. The liquid metal first low speed or high-speed casting filling mold into the mold cavity. The die casting mould has an active cavity surface with the cooling process of the liquid metal pressure forging.