Poly (Polycrystalline Diamond Powder)

Produkto aprašymas

Available sizes are

0-0.15, 0-0.2, 0-0.35, 0-0.5, 0.25-0.35, 0-1, 0-2, 2-4, 3-6, 3-7, 4-8, 4-9, 6-10, 6-12

Custom-made sizes are also available upon customers' demand.

Properties of Polycrystalline Diamond Powder

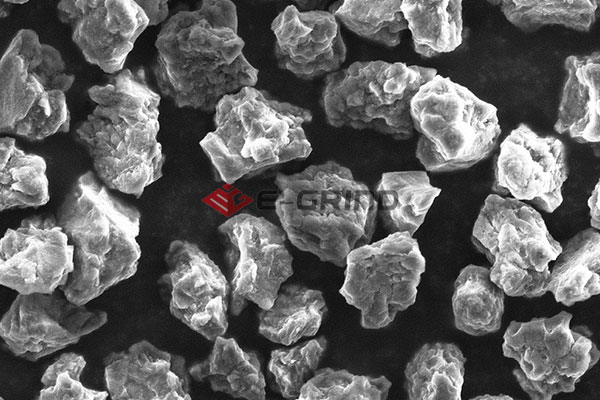

Detonation-synthesized polycrystalline diamond micro-powder

The structure resembles the rare natural polycrystalline black diamond, metallic-grey, superior toughness, self-sharpening.

The lapping and polishing efficiency of the detonation-synthesized polycrystalline diamond micro-powder is 2 to 4 times better compared with that of the mono-crystalline diamond that is naturally occurred or synthesized via the static pressure method, Silicon Nitride, Corundum, and other abrasive materials.

Polycrystalline diamond micro-powder allows the manufacturing of the smoothest surface possible:

a. When using polycrystalline diamond micro-powder of size 2-4micron to the polishing surface, Ra (roughness) < 1.6nm

b. When using polycrystalline diamond micro-powder of size 0-0.5micron to the polishing surface, Ra (roughness) < 1.3-1.4nm

c. When using polycrystalline diamond micro-powder of size 0-0.125micron to the polishing surface, Ra (roughness) < 0.1nm

Polycrystalline diamond can maintain its dull mono-crystalline structure by releasing the outer layer, hence will produce the most scratch free surface possible.