BALLISTIC SEPARATOR MACHINE

Popis produktu

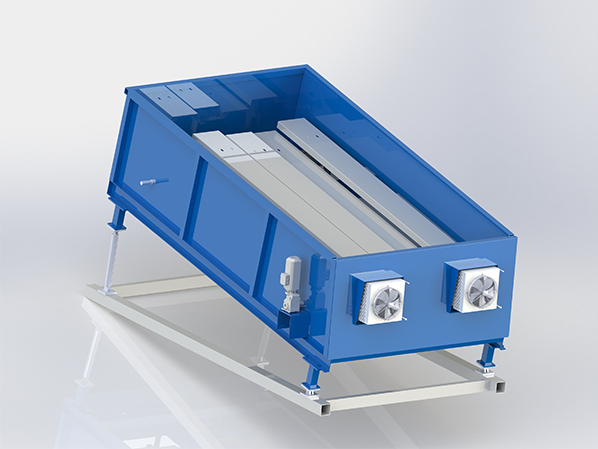

The ballistic screen produced by Hengchuang, a professional ballistic separator manufacturer, is a kind of garbage sorting machine for classifying materials based on the size, density, and shape of various components. The ballistic separator machine is the best sorting apparatus for processing and classifying household garbage, kitchen waste that has been processed after pressing, recycled paper, and other types of waste in various sectors. The trash on the dish-shaped sieve of the dish-picker vibrates as the sieve rotates. To achieve the goal of sorting, there is a space for ballistic separator machine between the dish sieve according to the size and weight of the trash. Inquiry ballistic separator for sale!

Ballistic Separator Machine Technical Advantages

Extremely fine sieving

The crankshaft is stable and long-lasting, and it is simple to replace.

Because the ballistic separator for sale is completely enclosed, dust and odor can be effectively managed.

The replacement of the ballistic screen plate is simple.

Ballistic Separator MachineApplication

Municipal garbage sorting with MSW segregation machine

Landfill waste sorting with landfill machine

Separation of waste paper with waste paper baling machine

Construction trash sorting with construction waste recycling equipment

Ballistic Separator Machine Working Principle

The screen plate of the Hengchuang ballistic separator recycling machine produces a reciprocal circular motion similar to bouncing under the influence of the drive motor, through the active and passive drive mechanism composed of active shaft and passive shaft connected with the support seat and ballistic screen plate to form a parallel four-bar mechanism, dividing the material input from the inlet into three kinds: 3D material with good rebound effect of large grain size, heavy and able to roll, underscreen mat. Three discharge hoppers each accept subpar, flat, and light 2D materials. The angle of the box and screen plate is modified by the hydraulic jacking system as a whole to adjust the bouncing lifting angle of the sorted materials since different materials' climbing and bouncing capabilities will be impacted by the tilting angle during the screening process. Contact the ballistic separator manufacturer for more info about the ballistic screen!