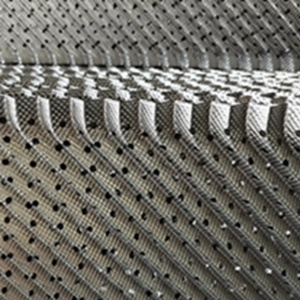

Melt Crystallizer

Опис товару

Accurately control the temperature and integrate a number of technologies for efficient purification.

Technical Principle of Melt Crystallizer

Characteristics of Melt Crystallizer

1

High product purity: The melt crystallization purity can be above 99.99% chromatographically pure according to customer requirements.

2

Low operating temperature: Generally, it is operated at atmospheric pressure and low temperature, with simple and safe operation.

3

Wide applicability: It is very difficult to separate isomers and chiral substances by distillation, while separation can be easily achieved by melt crystallization.

4

No solvents required: The crystallization process of melt crystallizer does not require the addition of other solvents, which can effectively avoid the increase of impurities caused by the introduction of solvents and environmental pollution.

5

Investment saving: There are no excessive requirements for equipment, which can reduce costs and equipment investment.

6

Energy conservation and environmentally friendly: The energy consumption of melt crystallization is generally only 10%-30% of that of distillation.

Applications of Melt Crystallizer

Petrochemical industry: 1,2,4,5-Tetramethylbenzene, Maleic anhydride, P-xylene, M-xylene

Biosynthetic materials: Dimethyl succinate, lactide, pentanediamine, long-chain dicarboxylic acid

Polymer monomer: Bisphenol A, acrylic acid, caprolactam, dimethyl terephthalate, hexanediamine

Coal chemical industry: Refined naphthalene, Fischer-Tropsch wax, cresol, naphthol

Electronic Chemicals: Ethylene carbonate, Dimethyl carbonate, Vinylene carbonate, Hydrogen peroxide, Phosphoric acid

Fine Chemicals: Benzoic acid, Phenylenediamine, Dichlorobenzene, Chloroacetic acid, Nitro chlorobenzene

For more information about chemical process definition, please feel free to contact us!