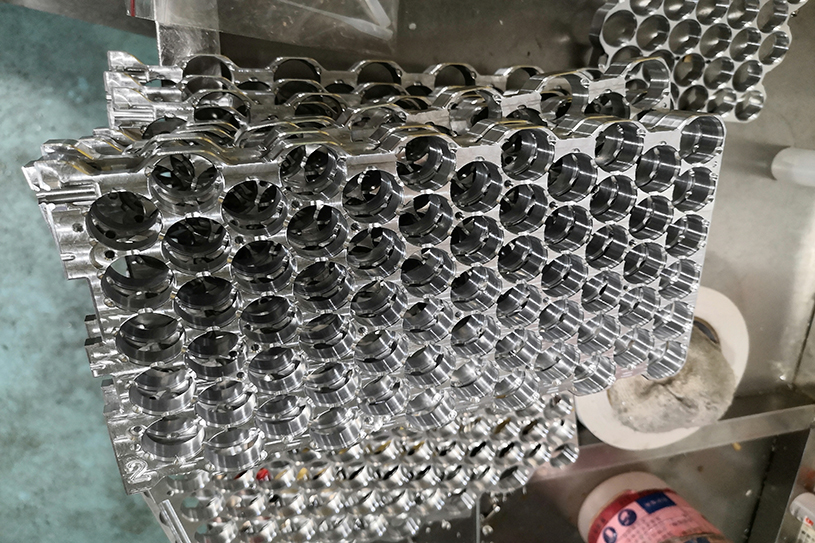

Custom Aluminum Parts

제품 설명

Custom Aluminum Parts

As one of professional CNC sheet metal manufacturing companies, HSJ is specialized in billet aluminum parts and custom aluminum component manufacturing.

Material :

aluminum (AS PICTURES)

Process :

CNC machine + deburrs

Type :

Broaching, Drilling, Etching / Chemical Machining, Laser Machining.

Material for Customized Aluminum Parts

1.Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc.

2.Brass Alloy:3602 / 2604 / H59 / H62 / etc.

3.Stainless Steel Alloy:303 / 304 / 316 / 412 / etc.

4.Steel Alloy :Carbon Steel / Die Steel / etc.

Designs:Customer supply 2D/3D drawing

Application of Customized Aluminum Parts

Customized aluminum parts are essential components in various industries, ranging from aerospace to automotive and construction. These aluminum parts are generally designed to meet the specific requirements of a particular application. As a result, companies are increasingly relying on the services of custom aluminum parts factories to fabricate bespoke aluminum parts that align with their unique specifications. The aluminum custom parts are predominantly used in applications that require high strength-to-weight ratio, corrosion resistance, and durability. Customized aluminum parts have become a critical aspect of advanced manufacturing, enabling companies to build better, stronger, and more efficient products that cater to their clients' needs. This demand has led to a rise in custom aluminum parts factories, which leverage advanced fabrication processes and computer-aided design to produce precise and reliable aluminum components.

As a professional customized custom aluminum parts factory, we supply different types of CNC billet aluminum parts, such as CNC AUTO parts, CNC electronic parts, CNC milling parts, and so on. The custom billet parts are highly valued by customers from wide range of industries including Auto/Electronic/Aerospace/Industrial/RF Connector/motorcycle.

Surface Treatment and Packing Options for Customized Aluminum Parts

We can offer surface treatment like Polishing, Sandblasting, Painting, Powder coating ,Galvanizing, Chrome plating,Black oxidation, Nickel plating, Heat treatment,Chemical film and Brush coating.

Packaging :wooden box, pallet, carton, PVC tray, PP bag as the customer required.

If necessary, welcome to consult for your custom aluminum component parts!

Why Choose HSJ FOR Customized Aluminum Parts Service?

Our customized aluminum parts offer a range of benefits to various industries, including aerospace, automotive, and construction. These custom machined metal parts are designed and manufactured based on specific client requirements, making them a perfect fit for their intended applications. Here are the reasons why you chose our CNC billet aluminum machined parts.

Highly resistant to corrosion. Aluminum is naturally resistant to corrosion, and our aluminium custom parts are treated with special coatings to prevent rust, oxidation, and other forms of damage. This makes them ideal for use in harsh environments or structures where durability is required.

Light Weight. Our custom billet parts are also beneficial due to their lightweight nature. Aluminum is significantly lighter than other metals, making it an ideal choice for applications such as aerospace, where weight is critical. This makes our aluminium custom parts an excellent choice for clients looking to reduce material weight and enhance the performance of their products.

Experienced Engineers. We pride ourselves on being one of the leading custom CNC aluminum parts suppliers in the industry. Our team of skilled engineers and machinists employ CNC billet aluminum machining to produce highly accurate and complex components. This allows us to offer our clients the highest level of precision and quality assurance, ensuring that the final product meets or exceeds their expectations.