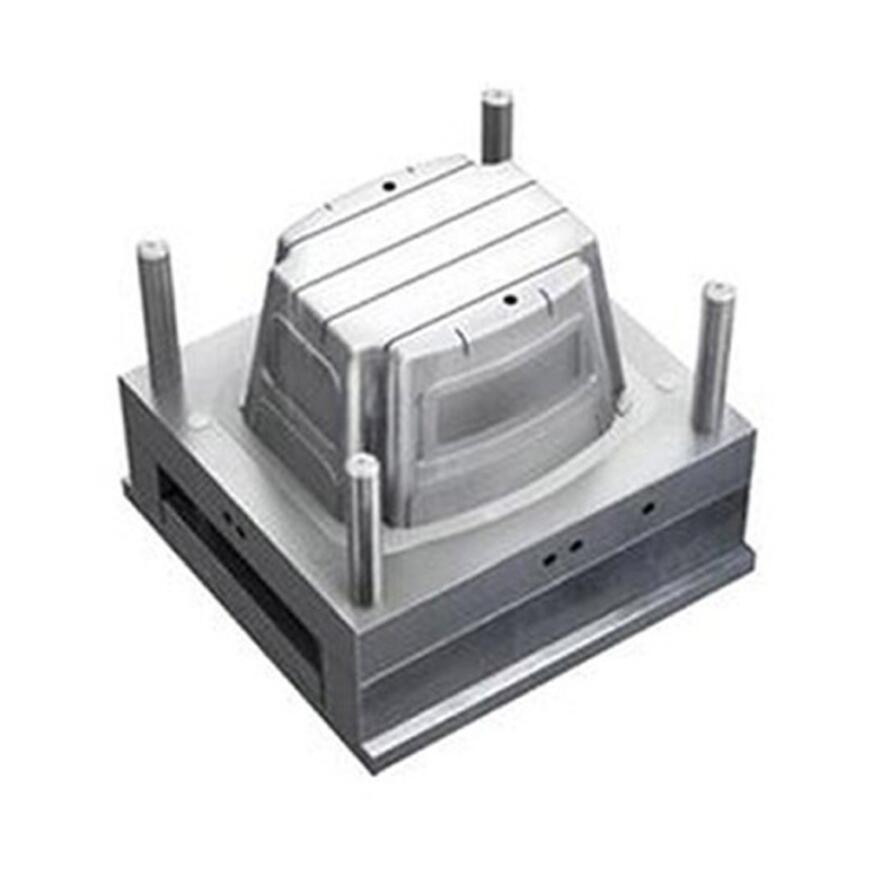

Lightweight Adult Children Plastic Chair And Stool Injection Mould

Product omschrijving

Our company mainly manufactures adult plastic chair and stool moulds and children's plastic chair and stool moulds. The plastic chair and stool injection mould has a long service life, and high quality achieves high quality.

In daily life, because the plastic chair and stool are light and convenient, it is convenient and safe to use. Some outdoor plastic chairs and stools are also welcomed by many people, and some coffee shops, restaurants, etc. also use a large number of plastic chairs and stools.

More and more people choose to buy plastic stools instead of wooden stools. The demand for plastic chair and stool has increased, and at the same time, people have a new demand for the design of plastic chairs and stools, thus promoting the development of our plastic chair and stool mould industry.

If you have an inquiry for plastic chair and stool injection mould, please contact our factory, thank you.

Mold material

Ordinary products use high-quality Shanghai Baosteel P20 (hardness 28-32hrc), 718 (hardness 32-38hrc), high-quality S45c template, self-made mold base or LKM standard mold base. High-precision and high-demand products use imported German steel: 2738, 2344, 2083, 8407, NAK80 and other steels.

Plastic chair and stool mold customization

Customized molds can be made according to customer requirements, and sample processing.

Customization Instructions

1. The customer provides drawings or product samples, and we preliminarily calculate the price.

2. The customer confirms the price, receives the customer's deposit, connects with the technology, and conducts product analysis.

3. Both parties confirm the final drawings and technical parameters. Carry out mold design and processing.

Process Type

Injection Molding Mold

Design software

Moldflow, UG, PROE, AUTOCAD, etc.

Plastic material

HDPE/PP

Main processing equipment

CNC, CNC milling machine, God drilling, milling machine, grinding machine, fine carving, wire cutting, EDM.

Number of cavities

Single cavity

Gate

Hot runner, cold runner

Waterway

The scientific and reasonable waterway arrangement design can increase the cooling effect by 30%, ensure that the mold is cooled evenly during production and molding, effectively shorten the production cycle, and prolong the service life of the mold.

Mold Processing

Inserts or mold lettering can be added according to customer requirements

Polishing - increase product surface gloss

Nitriding - reducing the deformation of the mold, increasing the surface hardness and wear resistance of the mold, making the mold more durable and extending the life of the mold.

Mold life

45# :300,000-500,000 shots /P20: 500,000 shots

Mould Packaging

Wooden Box

Production cycle

40-55 days

Origin

Zhejiang · Taizhou Huangyan

our website is https://www.mould-factory.net/

Import / export

1.00 Pack

Kostprijs, verzekering en vracht

T/T