Automatic bread ring production line using the tunnel oven

Product description

The line is designed to produce a large range of bread rings.

Classic bread rings producing technology includes the following steps:

• dough cooking;

• rubbing;

• dough proofing;

• half-finished product forming (dough rolling);

• laying half-finished product into the baking tray;

• stacking tray on trolley;

• proofing of pieces on trolleys in proofing chambers;

• baking on trolleys in rotary ovens;

• cooling on the trolleys;

• baked bread rings taking down from trolleys and baking trays;

• pre-packing (weighing)

• It should be about 7-10 people for the traditional type of production.

Our technology has reduced a lot of stages, and allowed us to get a high quality product with an amazing shine. Our line includes the following steps:

• dough cooking;

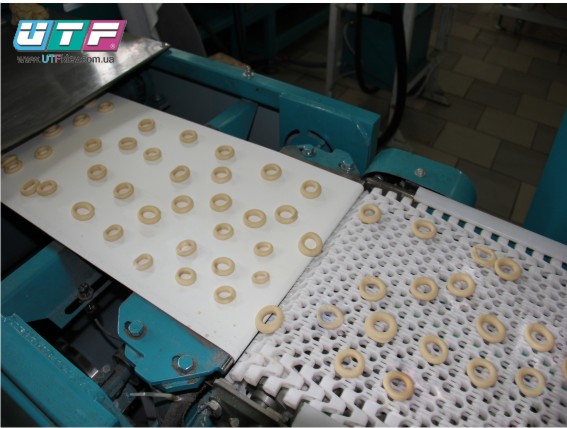

• half-finished product forming (dough rolling);

• steam treatment on stainless belt of tunnel furnace;

• baking in tunnel furnace;

• cooling on the conveyor;

• pre-packing (weighing)

• For our type of production it is needed 1-2 people to prepare the dough.

Further the line works in automatic mode.

Invented by us technology of steam treatment of half-finished products allows to get rid of dough rubbing and proofing, and gives already baked bread rings an excellent shine. As the experience showed, a "Brilliant (shining) bread rings" are more interesting for the buyer! Also it’s important to notice that our tunnel oven has a very wide range of temperature control and speed (time) of baking. That allows you to configure a line under any type of bread rings products. Also it is possible to bake different kinds of pastries, muffins and other confectionery in this tunnel oven.

The line includes:

• dough kneading machine for stiff dough;

• rolling and dividing machine;

• tunnel oven with steam chamber and steam utilizing system;

• steam generator;

• conveyor for cooling.

* Also, the line can be equipped with additional equipment (flour-sifter, rendering tank, weights, vat dumper, sach dumper, etc.) and packaging machines (semiautomatic).