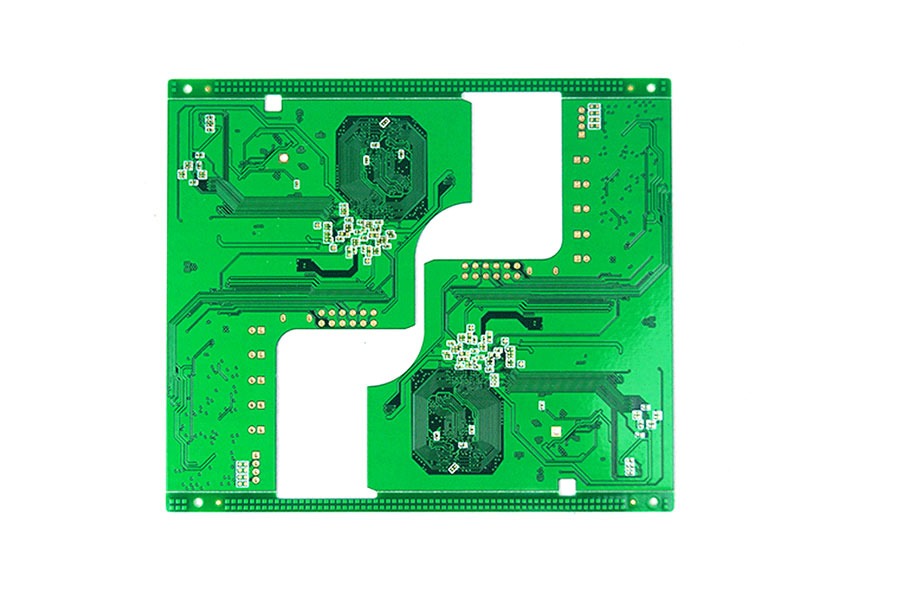

Automotive PCB

ఉత్పత్తి వివరణ

Automotive electronic products have different reliability requirements for automotive printed circuit board in different parts, Huihe Circuits’ car PCBs have passed the IATF16949 automotive quality management system standard, Strictly follow the requirements of the control plan to produce, monitor, record and analyze, ensure the stability of process parameters and the traceability of the production process.

Automotive Circuit Board Advantages

Huihe Circuits knows that the reliability of automotive PCB is equivalent to the reliability of automobiles, so it is necessary to ensure that the reliability of automotive electronics meets the requirements of service life and environmental tolerance. The rc remote control board used in the automotive electronic system needs to withstand the test of various environmental changes, such as temperature and humidity, climate, acid mist, vibration, electromagnetic interference, current impact, etc.; in order to ensure the PCB board application normal life cycle, the rc car pcb needs to meet high reliability, high integration, high The characteristics and requirements of heat dissipation, high current (thick copper), light weight and miniaturization, and embedded devices. For example, the high-voltage control system of a new energy electric vehicle uses a strong current board to integrate the original scattered high-voltage device parts, scattered DC/charge/discharge/MCU and other functional parts on an automotive printed circuit board. The density has increased several times, but The structural space should be saved by 30%, and the manual assembly efficiency should be increased by 50%. Inquiry Huihe Circuits PCB board maker for more solutions.

Automotive PCB Test Standards

Under this development trend, Huihe Circuits has taken the following measures to ensure the high reliability of automotive circuit board for automotive electronics: passed IATF16949 automotive quality management system standards; automotive electronic products have different reliability requirements for printed circuit boards for sale in different parts, and fully understand these requirements and Select appropriate materials and PCB automotive production processes, reliability testing and testing according to characteristics; formulate material selection rules; select appropriate materials according to the use parts of automotive electronic products during engineering planning; strictly follow the requirements of the control plan for car circuit board production, monitoring and recording ; key processes and key characteristics are monitored and analyzed by SPC; to ensure the stability of process parameters and the traceability of the PCB automotive production process; based on the IPC-TM-650 standard, a set of systematic and strict product performance testing methods and evaluations have been established Mechanism, including thermal cycle test, high temperature thermal shock, salt spray test, high current shock, high voltage resistance, electromigration, etc.