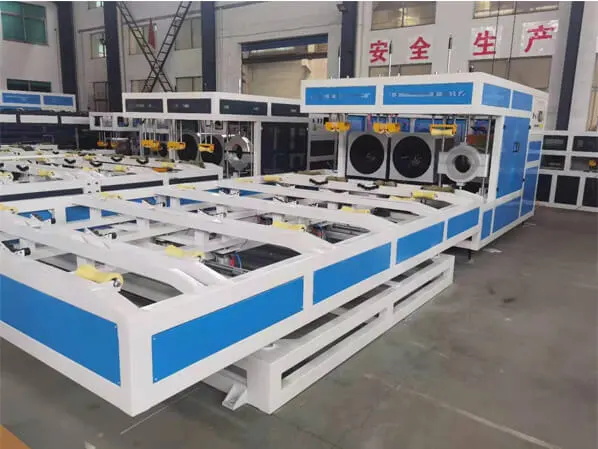

PVC Pipe Belling Machine

Описание товара

Pipe Belling Machine is suitable for the belling of UPVC (PVC-UH) plastic pipes. The PVC belling machine has the advantages of high automatic, stable and reliable performance, convenient operation and so on. It can be used in combination with the plastic pipe production line or a stand-alone machine. QING CHEN YU plastic pipe belling machine is mainly composed of a feeding traction mechanism, a heating mechanism, a flared mechanism (including flared die), and a support frame. It has high degree of automation, stable and reliable performance and convenient operation; the internal inflation pressure is shaped and the wall thickness is uniform; The belling can be different according to the plasticity of the material. The belling die can be expanded first and then casing, or first casing and then expansion. In general, our plastic PVC pipe belling machine has strong process adaptability, smooth flaring and obvious steps, consistent and intact size.

Features of PVC Pipe Belling Machine

It has efficient energy consumption, reducing your electrical bill and operating costs.

We use parts from renowned international brands.

The machine can produce two belling styles: “U” and “R” types.

The automatic belling machine can be integrated into a production line or used independently.

We offer a wide range of mold sizes from OD 20mm to 630mm.

The multilingual touch screen makes it easy to program the machine, reducing operator training time.

Our pipe belling machine incorporates advanced technology and is built for durability, maintaining good condition over many years.

The belling machine features a strong frame made from welded cold-drawn steel pipes.

We can easily customize the machine to meet your specific requirements, including the PVC four-pipe belling machine.

Key Components of PVC Pipe Socketing Machine

Feeder Device: The feeder device, supported by the frame, moves the pipe horizontally with stability and high accuracy.

Heating: Our PVC belling machine uses electrical heaters for precise contact heating of the bell-forming section, or infrared short wave heaters for smaller pipes. Depending on softening needs, multiple ovens may be required; we can recommend the appropriate number.

Mould: For U type belling, a plain mould is used. For R type belling, a mechanical mould with collapsible and expandable inserts forms the groove. We provide easily interchangeable moulds of various sizes.

Cool Water Spray System: Circulating water jets mounted on the belling station cool the pipes after forming, making them resistant to further transformation. Alternatively, air can be blown onto the pipe surface for cooling.

Hydraulic Components: Hydraulic systems, using incompressible fluid to transmit force, move mechanical parts. In the automatic belling machine, hydraulic components include the cylinder that grips the heated pipe in the belling station and moves the mould.

Electrical Components: The belling machine's main electrical components include PLC-controlled control components and the power supply. A Siemens panel/touch screen provides access to all machine controls and allows for presetting to enable automatic operation.

For more information about belling machine price, please feel free to contact us!